Projets de mécanique industrielle et de tuyauterie sanitaire

Maintenance industrielle (mécanique, électromécanique et tuyauterie sanitaire)

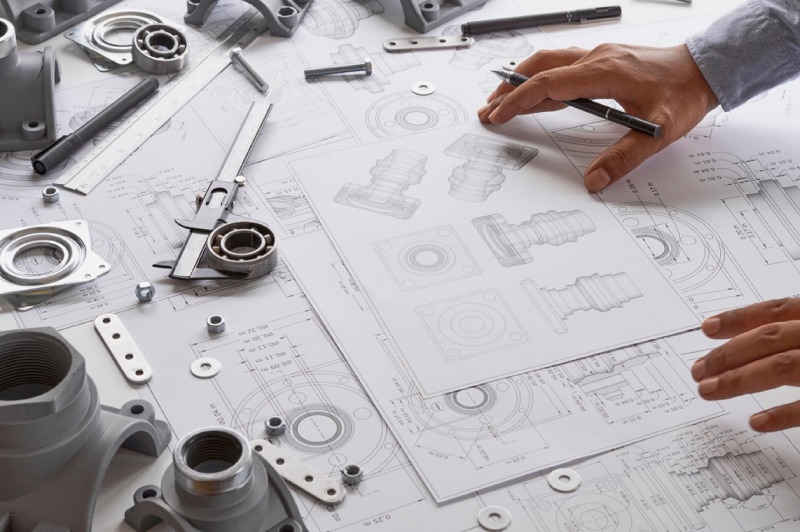

Dessin 2D et 3D, prise de mesures sur site, conception et ingénierie

Gestion de projet

Fabrication diverse et sur mesure (réservoir, plateforme; acier, stainless et aluminium)

Support technique et service d'urgence 24h/24

70 ans+

en tant que leader

de l'industrie

de l'industrie

Niveau de

satisfaction client le plus élevé de

notre industrie

satisfaction client le plus élevé de

notre industrie

Soutien

professionnel 24 h/24 et 7 j/7

professionnel 24 h/24 et 7 j/7